- Home Page

- Company Profile

-

Our Products

- Coupling

- Resilient Or Grid Spring Coupling

- Nylon Gear Coupling

- Pin Bush Coupling

- Brake Drum Coupling

- Chain Coupling

- Fenner Gear Coupling

- Star Coupling

- Customised Coupling

- Fluid Coupling

- Nylon Sleeve Gear Coupling

- Universal Coupling

- Bellow Coupling

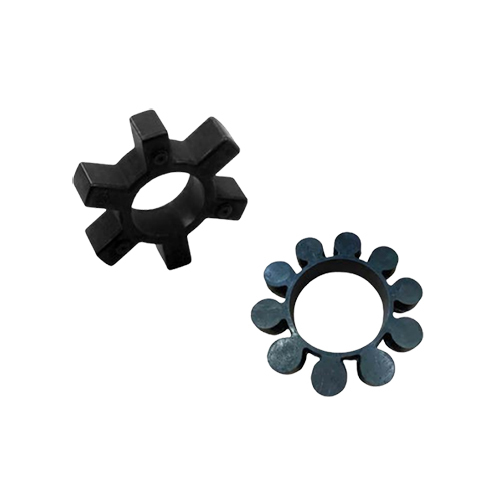

- Flexible Coupling Spider

- Fenner Coupling

- Flender .

- Lovejoy Coupling

- Universal Joints

- Grid Spring Couplings

- Tyre Coupling

- Disc-O-Flex Coupling

- Encoder Coupling

- EN8 Half Gear Coupling for industrial

- Sprocket Chain Wheel

- Gear and Spares

- Industrial Coupling

- Flexible Coupling

- Sprocket

- Pulley

- Gears

- Chain

- Rubber Product

- Roller

- Taper Lock Pulley

- Love Joy Coupling

- Universal Joint Couplings

- Industrial Chain Sprocket

- Gear Coupling

- RESILIENT COUPLING

- Roller Chain

- Pharma Machinery

- Disco Flex Coupling

- Rack Pinion

- V Groove Pulley

- Plummer Block

- Conveyor Pulleys

- Conveyor Chain

- Fenner V Belt

- Jaw Coupling

- Tyre Coupling

- Drive Chain

- Rotex Coupling

- Metal Bellow Coupling

- Timing Pulley

- Conveyor Roller Idler

- Shaft Couplings

- Crown Pinion

- ROTEX SPIDER

- Honey Comb Chain or Belt

- Slew Ring Bearing

- Chain Coupling

- Cardan Shaft

- Conveyor Roller

- Servo Coupling

- Normex Coupling

- Worm Gear and Shaft

- Half Gear Rigid Coupling

- Industrial V Belts

- Slat Chain

- Encoder Coupling

- Piv Chain

- Rotary Airlock Valve

- Bearing Parts & Components

- Locking Assembly

- Coupling

- Extra Info

- Contact Us

- Coupling

- Sprocket Chain Wheel

- Gear and Spares

- Industrial Coupling

- Flexible Coupling

- Sprocket

- Pulley

- Gears

- Chain

- Rubber Product

- Roller

- Taper Lock Pulley

- Love Joy Coupling

- Universal Joint Couplings

- Industrial Chain Sprocket

- Gear Coupling

- RESILIENT COUPLING

- Roller Chain

- Pharma Machinery

- Disco Flex Coupling

- Rack Pinion

- V Groove Pulley

- Plummer Block

- Conveyor Pulleys

- Conveyor Chain

- Fenner V Belt

- Jaw Coupling

- Tyre Coupling

- Drive Chain

- Rotex Coupling

- Metal Bellow Coupling

- Timing Pulley

- Conveyor Roller Idler

- Shaft Couplings

- Crown Pinion

- ROTEX SPIDER

- Honey Comb Chain or Belt

- Slew Ring Bearing

- Chain Coupling

- Cardan Shaft

- Conveyor Roller

- Servo Coupling

- Normex Coupling

- Worm Gear and Shaft

- Half Gear Rigid Coupling

- Industrial V Belts

- Slat Chain

- Encoder Coupling

- Piv Chain

- Rotary Airlock Valve

- Bearing Parts & Components

- Locking Assembly

Showroom

Couplings are instrumental in connecting motor and shafts for power transmission purpose. These machine components are also utilized for establishing connection between two shafts for transmission of torque. Long working life is one of their key aspects.

Sprocket Chain Wheels are useful for the power transmission as well as conveyor systems. They are highly reliable and efficient. They are apt for the applications with limited torque loads and shock. They have a mechanical advantage and enable a smooth chain engagement as well as release.

The Gear and Spares are efficient as well as simple to assemble. Their teeth are simple to align. These have minimal power loss due to the occurrence of slippage. They can be used at high speed and must be in a parallel position. These are not as strong as other gear wheel.

Industrial Couplings are the flexible couplings, utilized to connect two shafts collectively at their ends. They are apt for the purpose of transmitting power as well as rotational motion from one line to another. These can transmit the high torque even at high speed.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese